|

Input & Output Power

|

- Input: 208 - 240VAC, 20 A, 50/60 Hz, single phase

- Total Power required: 5 KW ( including pump)

- other 3 phase voltage is available upon request

- Output: 0 - 8VAC max. and 200A Max. (1600 W Max. )

|

|

Vacuum Chamber

|

- Stainless steel chamber: 300mm ID. x 360 mm Height, Sand-blasting electrolytic polishing surface

- 100 mm observation window in front of the chamber

- Hinged-type door for easy sample loading

- Electrically-driven shutters are on top of each evaporation W boat, which allows evaporating 4 kinds of material one by one

- One KF40 port with a gate valve to connect to DN 100 ISO-K the turbo pump directly

- One KF16 port to connect the vacuum gauge

- Six CF35 ports to connect a necessary device (e.g. film thickness monitor)

|

Vacuum Pump ( optional)

|

- A high-speed turbo vacuum pump is optional at extra cost (click the picture left to see specs )

- Vacuum level: 5.0x10-6 Torr ( after 40 minutes of pumping )

- Limit vacuum: 5.0x10-7 Torr ( after baking at 100 -150°C)

- Leaking rate: 5.0x10-7 Pa.

- Vacuum Port: DN 100 ISO-K

- A mechanical pump () is better to install in series to initially achieve the vacuum level of 3E-3Torr, which is good for subsequent turbopumps to achieve the target vacuum level.

|

Evaporation Source

&

Sample Holder

|

- Four tungsten heating boats are included supported by water-cold electrodes

- The tungsten heating boat has dimensions 70L x 12W x 3H (mm). Spare W boat is available at extra cost)

- Each top of the boat has a manual operation shutter

- Built-in manual shutter allows evaporation source can be used without contamination

- 120 mm diameter rotating sample holder is on top of the chamber with a diameter of 300mm,

- The distance between the evaporation source and sample holder is 140-200 mm adjustable

- The sample stage with a heating function (up to 500 °C) is optional and is available upon request

|

In-situ thickness monitor optional

|

- Hi-resolution Film Thickness Monitor and Controller are optional (click the picture left to see detailed specs )

- The accuracy of thickness control is 1.0 Angstrom.

|

|

Control Unit

|

- Vacuum, thickness, and power control are integrated into one control box

- The Control Unit is separated from the vacuum chamber for easy moving

- You may place the control unit on top of the vacuum station

|

|

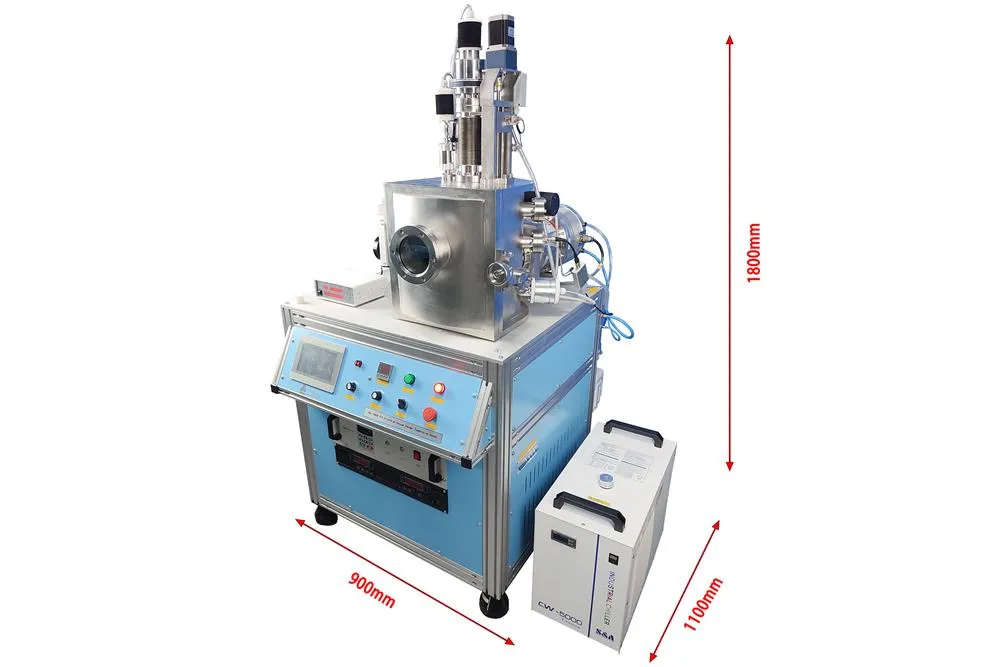

Facility Requirement

|

- Space: 250 SF with height > 6 feet

- Power: 208 - 240V AC, single phase with Max 10KW ( 50A breaker)

- Water: > 16L/minute flowing water required for electrode cooling. You may order recirculating water chiller to save water by clicking the picture below at extra cost.

|

|

Certificate

|

|